Komatsu VHMS Toolbox — Technical Analysis Tool Box v3.05+ (Vehicle Health Monitoring System)

Komatsu VHMS Toolbox — Technical Analysis Tool Box v3.05+ (Vehicle Health Monitoring System) is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Software only: Remote installation via TeamViewer

Laptop + Sofware: Free Shipping Worldwide FedEx Express

Description

Description

Komatsu VHMS Toolbox – Vehicle Health Monitoring System (v3.05+)

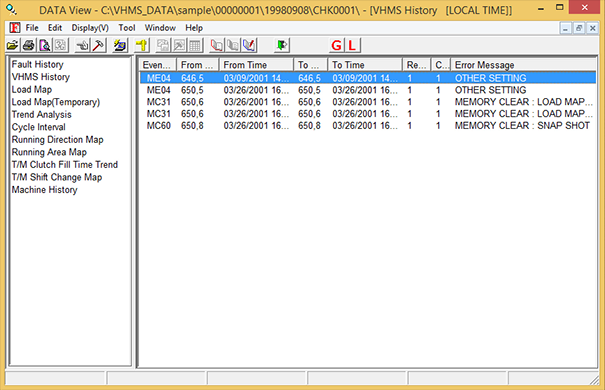

Komatsu VHMS Toolbox is the official diagnostic and data analysis software designed for Komatsu’s Vehicle Health Monitoring System (VHMS). This system is used in mining and large construction equipment to collect, analyze, and interpret performance data from machine control units, enabling predictive maintenance and minimizing unplanned downtime.

The Toolbox provides a direct interface between a technician’s PC and the machine’s VHMS controller, allowing comprehensive monitoring of operational parameters, error histories, and event trends. It is a critical tool for technicians working with Komatsu dump trucks, excavators, wheel loaders, and shovels equipped with VHMS modules.

Main Features

- Read and analyze historical data logs and operational trends from VHMS controllers.

- Display fault codes, alarm histories, and maintenance intervals with time stamps.

- Monitor engine, hydraulic, electrical, and transmission parameters in real time.

- Export raw data and event logs for offline trend analysis or reporting.

- Perform advanced performance evaluations for load, cycle time, and fuel efficiency.

- Supports all Komatsu VHMS-equipped machines used in mining, quarry, and large construction fleets.

Supported Equipment

- Rigid Dump Trucks: HD785, HD1500, 930E, 960E series.

- Hydraulic Excavators: PC8000, PC7000, PC4000, PC1250, PC1100, etc.

- Wheel Loaders: WA800–WA1200 series.

- Electric Shovels and Drills equipped with VHMS data collection units.

Software Information

| Brand | Komatsu |

| Type | Diagnostic & Data Analysis Software (VHMS System) |

| Version | v3.05+ |

| License | Lifetime / Offline |

| Languages | English (default interface) |

| Installed Size | ~20 MB |

| Operating System | Windows 7 / Windows 10 / Windows 11 (32-bit & 64-bit) |

| Delivery | Digital download + Remote installation through TeamViewer |

Hardware & Connection Requirements

- A PC with a functional RS-232 serial port or a USB-to-Serial interface (required for direct VHMS communication).

- Original Komatsu VHMS data cable (model-specific; referenced in the official VHMS Hardware Manual).

- Minimum 1 GB of free disk space for data logs and exports.

- An active Internet connection is required only during initial remote installation and activation.

Data Analysis Capabilities

- Download, decrypt, and visualize machine operating data.

- Generate maintenance trend graphs for components such as engine hours, hydraulic pressures, and load cycles.

- Cross-correlate performance parameters to identify degradation before failure.

- Export diagnostic summaries to Excel or CSV formats for maintenance reports.

Installation & Support

| Setup Time | Approx. 30 minutes via remote installation. |

| Requirements | Windows 10/11 (64-bit), stable Internet connection for setup. |

| Support | Remote installation, activation, and guidance for first data connection included. |

Payment & Refund Policy

| Payment Methods | Bank Transfer, Credit/Debit Card, Apple Pay, USDT (Crypto). |

| Refund Policy | Refundable before installation only. If installation cannot be completed, a full refund applies. |

Note:

The VHMS Toolbox is primarily used for technical data collection and analysis rather than direct ECU programming. It is ideal for OEM technicians, mining operations, and contractors who require performance-tracking and predictive-maintenance capabilities for Komatsu’s heavy-duty equipment fleet.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.